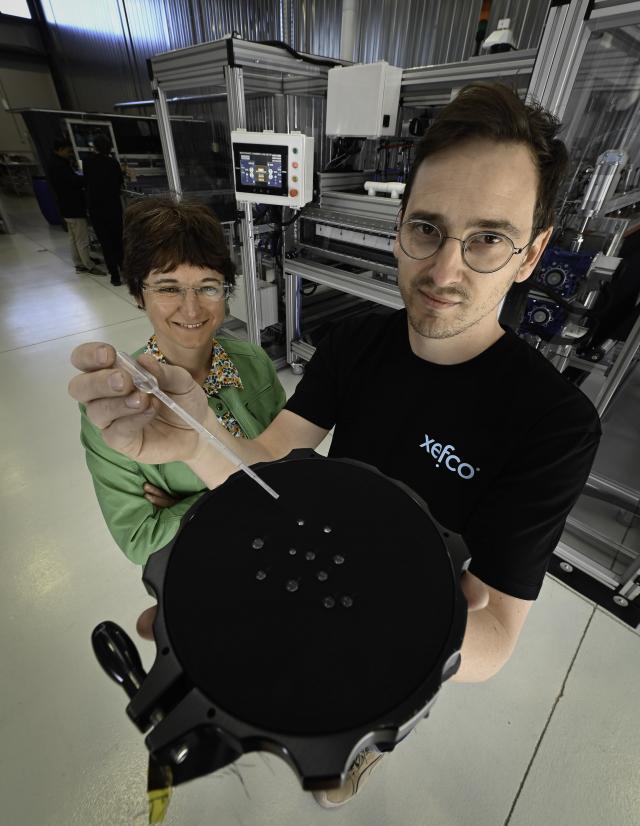

Deakin University and Geelong-based company Xefco have signed a partnership agreement to conduct research into how to colour clothes in a more sustainable way.

The research partnership will explore waterless processes that could potentially replace the water-intensive ones clothing manufacturers have used for centuries.

With common items like denim jeans requiring 75 litres of water to colour one pair, the clothing industry has plenty of room to improve its sustainability practices.

Xefco, a five-year-old company that has already provided insulation technology used by leading brands including The North Face, now has a pilot plant located at ManuFutures, Deakin’s advanced manufacturing hub at Waurn Ponds.

Associate Professor Alessandra Sutti, from Deakin’s Institute for Frontier Materials, said it was exciting to work with Xefco to hopefully reduce the world’s fashion footprint.

“If successful, the Ausora technology, which colours fabrics without the need for large quantities of water, will put us a step closer to more efficient and sustainable clothing manufacturing,” Associate Professor Sutti said.

Xefco chief executive Tom Hussey said research conducted at the company’s new pilot plant would test different materials, including specialised fabrics such as outdoor jackets and jeans.

“This is the first stage of Xefco’s vision for the technology, with the REACH project focused on demonstrating the commercial viability of the technology at pilot scale and developing processes so it can be scaled up for commercial production,” Mr Hussey said.

“Together, Deakin and Xefco will push the limits of innovation and see what is possible.”