Deakin University scientists have manufactured a revolutionary material that can clean up environmental oil spills.

The materials could save the earth from disasters such as a repeat of the 2010 Gulf Coast BP disaster that wreaked environmental havoc and cost a reported $40 billion.

The breakthrough material, which literally absorbs the oil like a sponge, is ready to be trialled by industry after two years of refinement in the laboratory at Deakin’s Institute for Frontier Materials (IFM).

A paper outlining the breakthrough was published in the journal Nature Communications.

Alfred Deakin Professor Ying (Ian) Chen, said the material was the most exciting advancement in oil spill clean-up technology in decades.

“Oil spills are a global problem and wreak havoc on our aquatic ecosystems, not to mention cost billions of dollars in damage,” Professor Chen said.

“Everyone remembers the Gulf Coast disaster, but here in Australia they are a regular problem, and not just in our waters.

“Oil spills from trucks and other vehicles can close freeways for an entire day, again amounting to large economic losses.

“But current methods of cleaning up oil spills are inefficient and unsophisticated, taking too long, causing ongoing and expensive damage, which is why the development of our technology was supported by the Australian Research Council.

“We are so excited to have finally got to this stage after two years of trying to work out how to turn what we knew was a good material into something that could be practically used.

“In 2013 we developed the first stage of the material, but it was simply a powder that had absorption capabilities, but you cannot simply throw powder onto oil.

“You need to be able to bind that powder into a sponge so that we can soak the oil up, and also separate it from water.”

IFM scientist Dr Weiwei Lei said turning the powder into a sponge was a big challenge.

“But we have finally done it by developing a new production technique,” Dr Lei said.

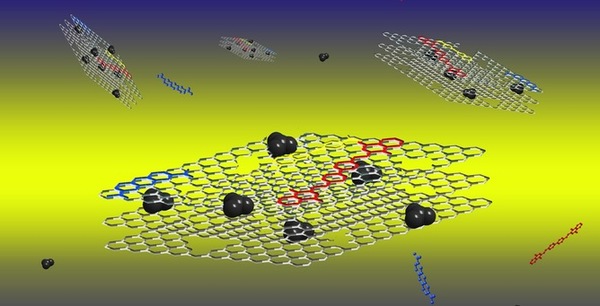

“The ground-breaking material is called a boron nitride nanosheet, made up of flakes just several nanometers (one billionth of a meter) in thickness with tiny holes which can increase its surface area per gram to effectively the size of 5.5 tennis courts.”

The research team, which included scientists from Drexel University, Philadelphia and Missouri University of Science and Technology, started with boron nitride powder known as “white graphite” and broke it into atomically thin sheets that were used to make a sponge.

“The pores in the nanosheets provide the surface area to absorb oils and organic solvents up to 33 times its own weight,” Dr Lei said.

Professor Yury Gogotsi from Drexel University said boron nitride nanosheets did not burn, could withstand flame, and be used in flexible and transparent electrical and heat insulation, as well as many other applications.